This report summarizes a two-year project, DE-FC07-011D13983 that concerns the gating of aluminum castings in permanent molds.

#Magmasoft price software

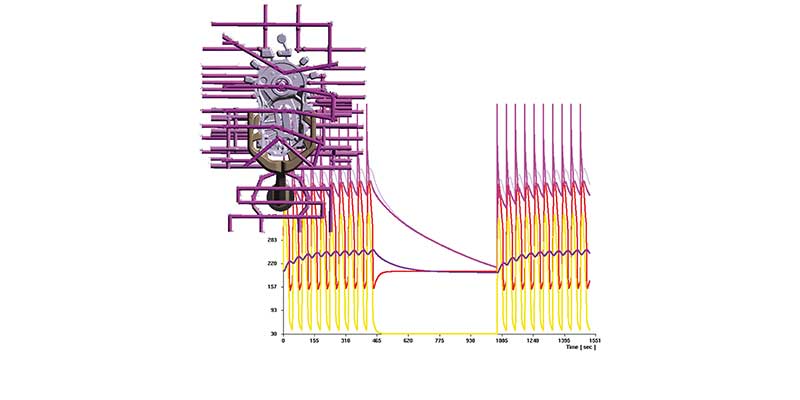

Computer models using the UES Procast and MagmaSoft finite element software can, after suitable adjustments, predict the flow pattern in the die cavity. In general, the smaller squeeze castings require higher die temperatures.

With the proper filling pattern, ingates, overflows and die temperature for a given die, very good tensile properties can be attained in squeeze casting. A higher metal pressure provides a more complete fill of the die including improved compensation for solidification shrinkage. Fanned gates allow use of higher fill velocity without excessive jetting. Straight gates are prone to case jetting of the metal stream even a low velocities.

This is best accomplished with a larger ingate to attain rapid filling without excessive velocity or jetting that occurs at high metal velocities. The molten metal has to fill the cavity before localized solidification occurs. The fan type ingate helps accomplish a rapid fill without high velocities. Fanned gates, particularly on the smaller section castings avoid jetting effects at the ingate end. The main conclusions from this investigation are as follows: The ingate size and shape are very important since it must remain open until the casting is solidified and pressure is maintained on the solidifying casting. The investigation of the resulting properties also included an analysis of the microstructure of the squeeze castings and the effect of the various structural constituents on the resulting properties. The mechanical properties of these test bars produced under different squeeze casting conditions were measured and reported. In more » addition to determining the effect of these casting variables on casting quality as measured by a flat plate die of various thickness, a number of test bar inserts with different gating designs have been inserted in the squeeze casting machine. The primary metal tested was an aluminum 356 alloy. The quality of the die casting was assessed by an analysis of both their surface condition and internal soundness. The variables studied include gating design, fill time and fill patter, metal pressure and die temperature variations. This investigation has studied the influence of the various casting variables on the quality of indirect squeeze castings primarily of aluminum alloys. These inserts were used to generate a broad range of processing conditions and determine their effect on the quality of the squeeze cast parts. A spiral ''ribbon insert'' for evaluation of molten metal fluidity was also fabricated. A significant number of inserts were designed and fabricated over the span of the project, primarily for squeeze casting different configurations of test bars and plates. Subsequently, a Sterling oil die heater and a Visi-Track shot monitoring system were added. The challenge of installation and operation of such industrial-size equipment in an academic environment was met successfully. A Lindberg 75k W electrical melting furnace was installed alongside. This study was initiated with the installation of a new production size UBE 350 Ton VSC Squeeze Casting system in the Metal Casting Laboratory at Case Western University.

0 kommentar(er)

0 kommentar(er)